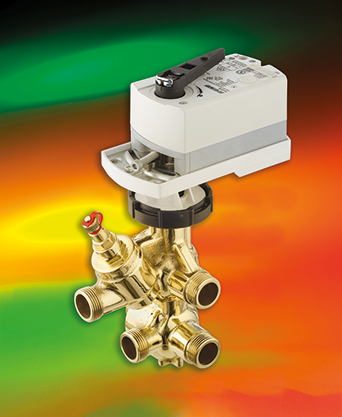

- With the Frese COMBIFLOW 6-Way solution, you need only one valve and one actuator to achieve complete pressure independent balancing and control. We have found a way to reduce some of the complexity in 4-pipe heating and cooling systems by minimizing the number of required valve components, says Przemyslaw Klosiak, Product Manager for Frese A/S.

4-pipe systems include heating and cooling ceilings, decentralized ventilation units, fan coil systems and convection heating and cooling units.

Until now it has only been possible to operate these systems dynamically by combining a static 6-way valve with a Pressure Independent Control Valve (PICV), thus requiring two valves, two actuators, connecting pipes and a control box.

- By integrating the DP controller in the valve, you have fewer connection points, which minimizes potential leakage problems, and with just one actuator you only need one data point to the building’s BMS, Przemyslaw Klosiak explains.

By designing the Frese COMBIFLOW 6-Way to cover a wide flow range, we have simplified the selection process, since a limited product range can cover a wide variety of needs. In addition, an extremely high flow capability has made it possible to downsize the valve dimension, further contributing to the valve’s compact design.

We have been a leading manufacturer of Pressure Independent Balancing and Control Valves for over 30 years, and the energy saving capabilities of the our patented Frese OPTIMA Compact will also be found in the new 6-way solution. These benefits are achieved through maximizing Delta T and eliminating overflows in the system. Additionally, the COMBIFLOW 6-Way has shown the lowest pressure loss known in the market, resulting in significant pump energy savings.

- Because all fluctuations in pressure are compensated by the integrated DP controller in the valve – that is, mechanically – the strain on the actuator is far smaller than in static solutions, where the differential pressure is regulated electronically by the actuator itself. This increases the durability of the actuator and contributes to energy efficiency through lower power consumption, Product Manager Przemyslaw Klosiak explains.

The valve also has a built-in pressure relief feature, which ensures that the terminal unit, i.e. the fan coil, will not break as a result of increased pressure when the valve is in closed position.

The Frese COMBIFLOW 6-Way is controlled by a rotating actuator with Modbus control, which allows the customer to program the individual cooling and heating flows via BMS, further simplifying both commissioning and daily operations. Included in our solution is a portable Modbus programming tool, which will assist in flow setting, configuration and diagnostics.

Flushing and cleaning the 4-pipe systems is simple and efficient with the Frese COMBIFLOW 6-Way, since the end user can simply remove the DP component, clean it, flush the system and reassemble the valve with minimal disruption to daily operations.

We have a patent pending on this integrated technology and are looking forward to cooperating closely with our European customers in the further development the Frese COMBIFLOW 6-Way product range.